Initially, as per the original DFS scope, Altech had proposed the production of 10,000 tons per annum (tpa) of Silumina Anodes TM product, comprising 1,000 tpa of high-purity alumina-coated metallurgical silicon incorporated into 9,000 tpa of similarly coated graphite (10% mix). The plant will now focus on solely producing alumina-coated metallurgical silicon product at a rate of 8,000 tpa. This product will be integrated into the graphite by the customers within their battery plants rather than at Altech's facility.

As a result of this increased production of the 'active' component, the output has expanded by a significant eightfold, rising from 15 GWh to 120 GWh.

According to feedback from potential customers, utilising their existing qualified graphite source is a priority.

Furthermore, although there is a marginal advantage in using alumina-coated graphite, the primary appeal for potential customers lies in integrating Altech-coated silicon into their battery products. Despite initial considerations regarding the benefits of coating graphite with alumina, such as the reduction of first-cycle loss, Altech's research has demonstrated that the cost-to-reward ratio for graphite is relatively minimal.

This recent adjustment to "all silicon" is expected to yield substantial improvements in the bottom-line economics. The most notable advantage lies in the ability to crack the silicon code, preventing expansion defragmentation, as well as curbing the significant first-cycle loss associated with silicon.

Battery manufacturers have the choice to either produce batteries with higher energy density or maintain their current energy density while reducing the graphite content. By decreasing the use of graphite, the cost of producing batteries can be reduced. However, the recent news about China, which accounts for approximately 90% of the global production of lithium-ion battery graphite, imposing limitations on the worldwide export of graphite, has begun to create challenges for battery manufacturers in Europe and the USA.

Altech is currently in talks with Ferroglobe, the European silicon partner of Altech, to boost the supply of metallurgical silicon for the enhanced Silumina Anodes TM project. Moreover, the Company has executed non-disclosure agreements (NDAs) with prominent automotive conglomerates in Europe and the United States, who have shown keen interest in acquiring commercial samples for their testing and qualification procedures. Considering the limited production capacity of Altech's R&D laboratory in Perth, the larger samples will be procured from the Silumina Anodes TM Pilot Plant in Saxony. The Pilot Plant is nearing completion and is expected to be operational in the early part of the upcoming year.

Managing Director Iggy Tan emphasised that the substantial increase in Silumina Anodes TM output by eightfold, achieved without significant changes in the plant or capital costs, represents a notable advancement in Altech's business strategy. Mr Tan highlighted the increasing demand in the lithium-ion battery industry for higher-density batteries, emphasising the necessity to reduce reliance on graphite, particularly in light of the export restrictions imposed by China. Mr Tan expressed confidence that the incorporation of Altech's alumina-coated silicon would assist battery customers in addressing these concerns. Mr Tan further conveyed his enthusiasm regarding the enhanced business model, indicating a positive outlook for the company's future endeavours.

To Watch the Video, please visit:

https://www.abnnewswire.net/lnk/V1264337

About Altech Batteries Ltd:

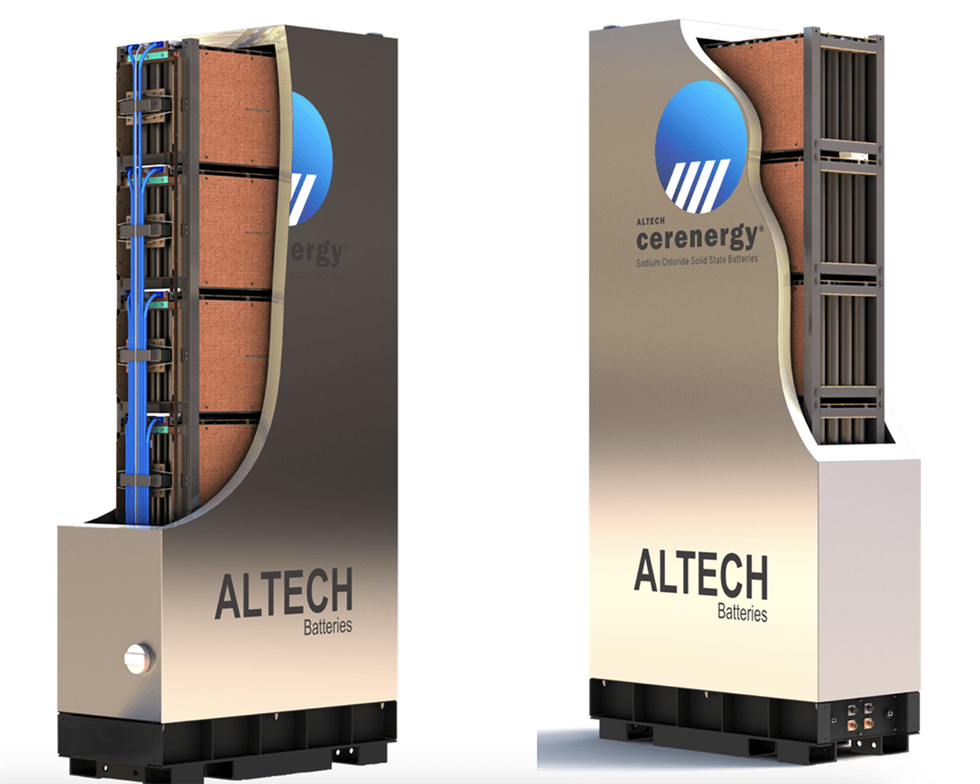

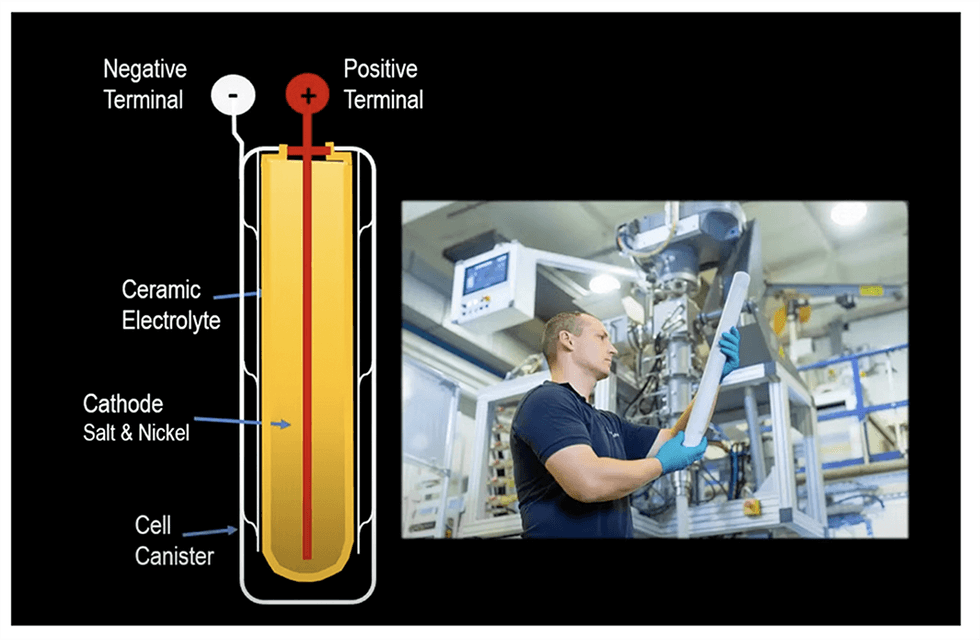

Altech Batteries Limited (ASX:ATC) (FRA:A3Y) is a specialty battery technology company that has a joint venture agreement with world leading German battery institute Fraunhofer IKTS ("Fraunhofer") to commercialise the revolutionary CERENERGY(R) Sodium Alumina Solid State (SAS) Battery. CERENERGY(R) batteries are the game-changing alternative to lithium-ion batteries. CERENERGY(R) batteries are fire and explosion-proof; have a life span of more than 15 years and operate in extreme cold and desert climates. The battery technology uses table salt and is lithium-free; cobalt-free; graphite-free; and copper-free, eliminating exposure to critical metal price rises and supply chain concerns.

The joint venture is commercialising its CERENERGY(R) battery, with plans to construct a 100MWh production facility on Altech's land in Saxony, Germany. The facility intends to produce CERENERGY(R) battery modules to provide grid storage solutions to the market.