(figures are unaudited and in US$ except where stated)

Strong quarterly production, safety and unit cost records, progress on growth

- Strong operating performance in the December 2020 quarter(1)

- Gold production of 535koz(2) and copper production of 35kt

- All-In Sustaining Cost (AISC) of $968/oz(2), delivering an AISC margin of 46% or $836/oz(3)

- Cadia records lowest ever quarterly AISC at negative $6/oz

- Safety Transformation Plan delivering results

- Record low TRIFR outcomes for Red Chris and Telfer

- Overall Group TRIFR of 1.6, an equal record low for a quarter

- Growth agenda advanced with significant progress made at the Havieron Project

- Initial Inferred Mineral Resource estimate of 3.4Moz of gold and 160kt of copper(4)

- Early works construction underway in relation to the box cut and exploration decline

- Renewable energy transition progressed with Cadia renewable energy Power Purchase Agreement

- Expected to help deliver a ~20% reduction in Newcrest’s greenhouse gas emissions from 2024

- A significant step towards achieving Newcrest’s target of a 30% reduction by 2030(5)

- New compensation, relocation and benefits sharing agreements signed at Lihir

- Environment Permit granted for Wafi-Golpu Project

Newcrest Mining Limited (ASX: NCM) (TSX: NCM) Newcrest Managing Director and Chief Executive Officer, Sandeep Biswas, said, “Our results for the December quarter were underpinned by a strong operational and safety performance together with significant advancements in our growth agenda and sustainability commitments.”

“Newcrest’s quarterly gold production was 6% higher than the prior period reflecting a stronger performance from Lihir and Telfer combined with a reduction in scheduled maintenance events in the quarter. Our world-class Cadia asset continues to break records, reporting its lowest ever quarterly All-In Sustaining Cost of negative $6/oz, which equates to an All-In Sustaining Cost margin of $1,821/oz on its almost 200,000 ounces in the quarter.”

“At Lihir, we are on track to release the outcomes of the mine optimisation study with our Half Year Results in February. The continued improvement of the handling and processing of the argillic ores has contributed to an increase in throughput and recovery, and culminated in a 13% increase in gold production in the quarter. We recently announced the signing of a new compensation, relocation and benefits sharing agreement with the mining lease area landholders, building on the strong relationships we have developed over recent years.”

“Red Chris and Telfer also achieved new safety records in the quarter, reporting their lowest ever injury rates. This fantastic achievement demonstrates the success of Newcrest’s Safety Transformation Plan and highlights the commitment and dedication of all our people in embedding the safety culture in our workplace.”

“In December 2020, we took a major step towards defining the potential of the Havieron Project with the announcement of an initial Inferred Mineral Resource estimate. In January 2021, the Board approved funding to construct the box cut, exploration decline and associated infrastructure, following receipt of the necessary regulatory approvals to commence these activities. With work now well underway at the Project, we see the potential of achieving commercial production from Havieron within the next three years.”

“During the period we also entered into a landmark renewable energy power purchasing agreement to secure a significant part of the future energy requirements at Cadia. This agreement is expected to help deliver a ~20% reduction in Newcrest’s greenhouse gas emissions, assist in maintaining competitive energy costs and is a significant step in achieving our target of a 30% reduction in emissions intensity by 2030.”

“Progress was also made at the Wafi-Golpu Project with the granting of the Environment Permit in December 2020, which is a prerequisite for the grant of a Special Mining Lease under the Mining Act,” said Mr Biswas.

| Highlights | Metric | Dec 2020 Qtr | Sep 2020 Qtr | YTD FY21 | YTD FY20 | FY21 Guidance | |

| TRIFR(6) | mhrs | 1.6 | 2.6 | 2.2 | 2.3 | ||

| Group production(2) | – gold | oz | 535,477 | 503,089 | 1,038,566 | 1,062,751 | 1,950-2,150koz |

| – copper | t | 34,557 | 34,763 | 69,320 | 62,468 | 135-155kt | |

| All-In Sustaining Cost(2),(7) | $/oz | 968 | 980 | 974 | 877(8) | ||

| Realised gold price(9) | $/oz | 1,815 | 1,837 | 1,826 | 1,446 | ||

| All-In Sustaining Cost margin(3) | $/oz | 836 | 847 | 842 | 569 | ||

Overview

Gold production was 6% higher than the prior period primarily driven by a reduction in scheduled maintenance events in the quarter, combined with a stronger operational performance from Lihir and Telfer. Gold production for the December 2020 quarter includes 31koz relating to Newcrest’s 32% equity interest in Lundin Gold Inc which owns the Fruta del Norte mine.

Newcrest’s AISC for the December 2020 quarter of $968/oz(2) was $12/oz lower than the prior period. The marginal improvement in Newcrest’s AISC/oz was primarily driven by the benefit of a higher realised copper price, higher copper sales volumes at Cadia and a reduction in the amount of production stripping. These benefits were largely offset by timing of gold sales volumes at Lihir, timing of sustaining capital expenditure and the impact of a strengthening Australian and Canadian dollar on operating costs.

| Metric | Dec 2020 Qtr | Sep 2020 Qtr | YTD FY21 | YTD FY20 | FY21 Guidance(10) | ||

| Group(2) | -gold | oz | 535,477 | 503,089 | 1,038,566 | 1,062,751 | 1,950-2,150koz |

| -copper | t | 34,557 | 34,763 | 69,320 | 62,468 | 135-155kt | |

| -silver | oz | 230,769 | 214,412 | 445,181 | 470,567 | ||

| Cadia | -gold | oz | 194,088 | 196,504 | 390,592 | 411,452 | 680-760koz |

| -copper | t | 26,643 | 25,329 | 51,972 | 45,423 | 95-105kt | |

| Lihir | -gold | oz | 200,173 | 177,337 | 377,510 | 381,500 | 720-820koz |

| Telfe | -gold | oz | 98,855 | 86,452 | 185,307 | 182,464 | 360-420koz |

| -copper | t | 2,443 | 2,384 | 4,826 | 7,273 | 10-20kt | |

| Red Chris(11) | -gold | oz | 11,375 | 12,636 | 24,012 | 11,294 | 45-55koz |

| -copper | t | 5,471 | 7,050 | 12,521 | 9,773 | 25-30kt | |

| Gosowong(12) | -gold | oz | – | – | – | 76,040 | |

| Fruta del Norte(2),(13) | -gold | oz | 30,986 | 30,160 | 61,146 | – | 95-110koz |

| Fatalities | Number | 0 | 0 | 0 | 0 | ||

| TRIFR(6) | mhrs | 1.6 | 2.6 | 2.2 | 2.3 | ||

| All-In Sustaining Cost(2),(7) | $/oz | 968 | 980 | 974 | 877(8) | ||

| All-In Cost(14) | $/oz | 1,349 | 1,275 | 1,310 | 1,029 | ||

| All-In Sustaining Cost margin(3) | $/oz | 836 | 847 | 842 | 569 | ||

| Realised gold price(9) | $/oz | 1,815 | 1,837 | 1,826 | 1,446 | ||

| Realised copper price(9) | $/lb | 3.26 | 2.97 | 3.12 | 2.66 | ||

| Realised copper price(9) | $/t | 7,187 | 6,548 | 6,878 | 5,864 | ||

| Average exchange rate | AUD:USD | 0.7303 | 0.7147 | 0.7225 | 0.6846 | ||

| Average exchange rate | PGK:USD | 0.2853 | 0.2872 | 0.2862 | 0.2940 | ||

| Average exchange rate | CAD:USD | 0.7667 | 0.7504 | 0.7585 | 0.7575 | ||

All figures are shown at 100% unless stated otherwise.

Operations

Cadia, Australia

| Highlights | Metric | Dec 2020 Qtr | Sep 2020 Qtr | YTD FY21 | YTD FY20 | FY21 Guidance | |

| TRIFR | mhrs | 7.5 | 3.6 | 5.5 | 4.3 | ||

| Total production | – gold | oz | 194,088 | 196,504 | 390,592 | 411,452 | 680-760koz |

| – copper | t | 26,643 | 25,329 | 51,972 | 45,423 | 95-105kt | |

| Head Grade | – gold | g/t | 0.95 | 1.02 | 0.98 | 1.18 | |

| – copper | % | 0.39 | 0.40 | 0.39 | 0.40 | ||

| Sales | – gold | oz | 194,183 | 195,146 | 389,329 | 398,648 | |

| – copper | t | 26,477 | 24,596 | 51,073 | 44,170 | ||

| All-In Sustaining Cost | $/oz | (6) | 113 | 54 | 167([15]) | ||

| All-In Sustaining Cost margin | $/oz | 1,821 | 1,724 | 1,772 | 1,279 | ||

Gold production of 194koz was 1% lower than the prior period due to lower grade and recovery, largely offset by the realisation of a number of debottlenecking initiatives in Concentrator 1 which, together with a reduction in scheduled maintenance events, culminated in a 7% increase in mill throughput.

Gold recovery was 2% lower than the prior period reflecting a reduction in mineral liberation and flotation residence time which was a consequence of the higher throughput rates. The completion of Stages 1 and 2 of the Cadia Expansion Project is expected to deliver increased recoveries at the higher throughput rates, as well as further increasing plant capacity to 35mtpa. The lower gold grade in the period was in line with expectations.

Mill throughput in the March 2021 quarter will be lower than the current period reflecting planned shutdowns for Concentrator 1 and the material handlings system.

Cadia has set a new quarterly record, reporting an AISC for the period of negative $6/oz which reflects a higher realised copper price, higher copper sales volumes and timing of sustaining capital expenditure. These benefits were partially offset by the impact on operating costs from the strengthening of the Australian dollar against the US dollar and higher royalty and concentrate treatment, refining and transporting costs.

Newcrest announced in December 2020 that it had entered into a 15 year renewable Power Purchase Agreement (“PPA”) with Tilt Renewables Limited, the owner and developer of the Rye Park Wind Farm, to secure a significant portion of Cadia’s future projected energy requirements. The PPA, together with the forecast decarbonisation of electricity generation in New South Wales, is expected to deliver a ~20% reduction in Newcrest’s greenhouse gas emissions and is a significant step towards the achievement of Newcrest’s targeted 30% reduction by 2030(16). The PPA will act as a partial hedge against future electricity price increases and will provide Newcrest with access to large-scale generation certificates which Newcrest intends to surrender to achieve a reduction in its greenhouse gas emissions.

In December 2020, Newcrest submitted the statement of environmental effects to the Department of Planning, Industry and Environment for Modification 14. The Modification seeks approval from the Department to increase Cadia’s current processing capacity from 32mtpa to 35mtpa and includes the proposal for the repair of the slumped section of the Northern Tailings Storage Facility (“NTSF”) together with a minor change to the footprint of the NTSF and Southern Tailings Storage Facility to allow for a change from upstream to centreline lift design.

The Molybdenum Plant is on track to be fully commissioned in the fourth quarter of FY21. The Molybdenum Plant is expected to deliver an additional revenue stream for Cadia in the form of a molybdenum concentrate which will be recognised as a by-product credit to AISC.

Lihir, Papua New Guinea

| Highlights | Metric | Dec 2020 Qtr | Sep 2020 Qtr | YTD FY21 | YTD FY20 | FY21 Guidance | |

| TRIFR | mhrs | 0.0 | 0.5 | 0.2 | 0.5 | ||

| Production | – gold | oz | 200,173 | 177,337 | 377,510 | 381,500 | 720-820koz |

| Head Grade | – gold | g/t | 2.27 | 2.34 | 2.30 | 2.38 | |

| Sales | – gold | oz | 170,308 | 210,831 | 381,139 | 362,955 | |

| All-In Sustaining Cost | $/oz | 1,438 | 1,283 | 1,352 | 1,154 | ||

| All-In Sustaining Cost margin | $/oz | 377 | 554 | 474 | 292 | ||

Gold production of 200koz was 13% higher than the prior period driven by an increase in throughput and recovery, partially offset by lower grade.

The higher throughput in the December quarter reflects the completion of scheduled maintenance events which commenced in the prior quarter, together with a reduction in unplanned downtime. Mill throughput also benefited from improved blending and operational practices combined with modifications to chutes and conveyors which improved the ability to process argillic ores.

Gold recovery improvements were realised through improved flotation performance notwithstanding gold head grades were 3% lower than the prior period as a result of lower mined ore and stockpile grades.

Additional modifications are planned in the March 2021 shutdown to manage the processing of argillic ores, including trommel spray upgrades, which will further increase confidence in managing the increased proportion of these ores.

Newcrest expects to announce the findings of its Lihir mine optimisation study in its Half Year Results which will be released on 11 February 2021. The mine optimisation study was focused on improving ore presentation to the processing plant, accounting for clay management study outcomes and optimising the integration sequence of the seepage barrier project with the mine schedule.

In accordance with Lihir’s bi-annual shutdown strategy, a planned shutdown will be executed in the March 2021 quarter which will result in a reduction in mill throughput when compared to the December 2020 quarter.

Lihir’s AISC was 12% higher than the prior period primarily driven by the timing of gold sales volumes and the timing of sustaining capital expenditure.

On 22 December 2020, Newcrest announced that it had signed new compensation, relocation and benefits sharing agreements with the mining lease area landholders at Lihir. It is expected that these new agreements will enhance socio-economic development outcomes for mining lease area landholders and enable benefits to be distributed directly to their intended beneficiaries. The agreements also enable the efficient and transparent distribution of compensation and benefits without a material increase in quantum.

Lihir – Material Movements

| Ore Source | Metric | Dec 2020 Qtr | Sep 2020 Qtr | YTD FY21 | YTD FY20 |

| Ex-pit crushed tonnes | kt | 1,918 | 1,236 | 3,154 | 2,614 |

| Ex-pit to stockpile | kt | 615 | 1,610 | 2,225 | 4,051 |

| Waste | kt | 4,793 | 6,269 | 11,063 | 9,471 |

| Total Ex-pit | kt | 7,326 | 9,115 | 16,440 | 16,137 |

| Stockpile reclaim | kt | 1,765 | 2,192 | 3,957 | 3,853 |

| Stockpile relocation | kt | 2,884 | 3,306 | 6,190 | 7,293 |

| Total Other | kt | 4,649 | 5,498 | 10,147 | 11,146 |

| Total Material Moved | kt | 11,975 | 14,613 | 26,587 | 27,283 |

Lihir – Processing

| Equipment | Metric | Dec 2020 Qtr | Sep 2020 Qtr | YTD FY21 | YTD FY20 |

| Crushing | kt | 3,683 | 3,426 | 7,109 | 6,467 |

| Milling | kt | 3,691 | 3,255 | 6,946 | 6,645 |

| Flotation | kt | 2,835 | 2,780 | 5,615 | 4,729 |

| Total Autoclave | kt | 1,998 | 1,592 | 3,590 | 3,658 |

Telfer, Australia

| Highlights | Metric | Dec 2020 Qtr | Sep 2020 Qtr | YTD FY21 | YTD FY20 | FY21 Guidance | |

| TRIFR | mhrs | 1.8 | 4.6 | 3.6 | 4.3 | ||

| Production | – gold | oz | 98,855 | 86,452 | 185,307 | 182,464 | 360-420koz |

| – copper | t | 2,443 | 2,384 | 4,826 | 7,273 | 10-20kt | |

| – gold | g/t | 0.94 | 0.86 | 0.90 | 0.91 | ||

| – copper | % | 0.09 | 0.09 | 0.09 | 0.15 | ||

| Sales | – gold | oz | 87,992 | 85,096 | 173,089 | 185,470 | |

| – copper | t | 2,152 | 2,311 | 4,463 | 6,998 | ||

| All-In Sustaining Cost | $/oz | 1,560 | 1,797 | 1,676 | 1,380 | ||

| All-In Sustaining Cost margin(17) | $/oz | 255 | 40 | 150 | 66 | ||

Telfer’s TRIFR outcome of 1.8 injuries per million hours worked is its lowest reported quarterly safety outcome on record. This significant achievement demonstrates the success of Newcrest’s Safety Transformation Plan in embedding safe practices and behaviours at its operations, reflecting strong visible safety leadership, proactive hazard reporting and a workforce committed to improve the safety culture at their workplace.

Gold production of 99koz was 14% higher than the prior period, driven by the completion of planned maintenance in the prior quarter enabling an increase in mill throughput, a 9% increase in gold grade, the injection wells pilot which has positively contributed to an increase in the realisation of Dump Leach ounces in the period and higher recovery. The 9% increase in gold grade reflects a higher proportion of underground ore feed with the 2% improvement in gold recovery attributable to the optimisation of sulphur grades through successful blending strategies.

Telfer’s AISC of $1,560/oz was 13% lower than the prior period reflecting lower site costs due to lower open pit mining activity and maintenance shutdown timing, the benefit to site operating costs from the 14% increase in gold production, a reduction in freight costs and a higher realised copper price. These benefits were partially offset by the impact on operating costs from the strengthening of the Australian dollar against the US dollar, gold and copper sales volumes being below production due to rain affected delays to shipping, timing of sustaining capital expenditure and an increase in exploration activities.

Red Chris, Canada

| Highlights(18) | Metric | Dec 2020 Qtr | Sep 2020 Qtr | YTD FY21 | YTD FY20 | FY21 Guidance | |

| TRIFR | mhrs | 1.8 | 11.1 | 6.7 | 16.9 | ||

| Production | – gold | oz | 11,375 | 12,636 | 24,012 | 11,294 | 45-55koz |

| – copper | t | 5,471 | 7,050 | 12,521 | 9,773 | 25-30kt | |

| Head Grade | – gold | g/t | 0.42 | 0.40 | 0.41 | 0.28 | |

| – copper | % | 0.45 | 0.46 | 0.46 | 0.45 | ||

| Sales | – gold | oz | 12,641 | 11,834 | 24,475 | 9,789 | |

| – copper | t | 6,072 | 6,642 | 12,714 | 8,679 | ||

| All-In Sustaining Cost | $/oz | 3,278 | 2,621 | 2,961 | 2,323([19]) | ||

| All-In Sustaining Cost margin | $/oz | (1,463) | (784) | (1,135) | (877) | ||

Red Chris’ TRIFR outcome of 1.8 injuries per million hours worked is its lowest reported quarterly safety outcome since Newcrest acquired its 70% interest and became operator of the Red Chris mine. This significant milestone highlights the success of Newcrest’s Safety Transformation Plan in transforming on-site safety behaviours and improved working conditions. Red Chris continues to build on its safety reporting culture and incident investigation with a particular focus on hazard identification and mitigation through sound pre-task planning and on-task assessment.

Gold production of 11koz was 10% lower than the prior period primarily driven by lower mining and throughput rates. Mining in the open pit was impacted by excessive melt water from a higher than average winter snow pack and unseasonal rain in the quarter which flooded both open pits and caused extended periods of adverse road conditions. This delayed ore release from Phase 4 and led to material handling issues in the primary crusher, coarse ore stockpile and mill feed systems. These impacts were partially offset by the benefit of a higher residence time in the circuit which improved gold recovery and a higher feed grade.

Red Chris’ AISC of $3,278/oz was 25% higher than the prior period driven by higher operating costs in the open pit due to unseasonably high rainfall, lower copper sales volumes and the impact to site operating costs from a strengthening Canadian dollar against the US dollar. These impacts were partially mitigated by a higher realised copper price and lower sustaining capital expenditure.

Over the course of FY21, Red Chris is planning to implement a number of additional improvement initiatives across the site including a new fleet management system, the replacement of the conventional CAT 793 truck tubs with high performance trays to realise payload benefits and a number of throughput and recovery related projects.

The latest drilling results for Red Chris are included in the December 2020 Quarterly Exploration Report which was also released today. Newcrest expects to commence the construction of the box-cut for the exploration decline later this quarter, subject to regulatory approvals.

Fruta Del Norte, Ecuador

As announced on 30 April 2020, Newcrest acquired the gold prepay and stream facilities and an offtake agreement in respect of Lundin Gold Inc’s Fruta del Norte mine for $460 million. In the December 2020 quarter, Newcrest received net pre-tax cash flows of ~$26 million from these financing facilities.

Included within Newcrest’s gold production for the December 2020 quarter is 31koz relating to Newcrest’s 32% equity interest in Lundin Gold Inc, the owner of the Fruta del Norte mine.

Project Development

Havieron, Western Australia

The Havieron Project is located 45km east of Newcrest’s Telfer operation and is operated by Newcrest under a Joint Venture Agreement with Greatland Gold plc.

In December 2020, Newcrest released an initial Inferred Mineral Resource Estimate for the Havieron Project of 52Mt @ 2.0g/t Au and 0.31% Cu for 3.4Moz Au and 160kt Cu(20). Mineralisation remains open in multiple directions outside of the initial Inferred Mineral Resource estimate, which indicates the possibility that the resource could continue to grow over time with additional planned drilling activity.

Additionally, on 13 January 2021 Newcrest announced that its Board had approved funding of A$146 million (~US$112 million(21)) for the construction of the box cut, exploration decline and associated surface infrastructure at the Havieron Project. This followed receipt of the necessary regulatory approvals to commence these construction activities.

Work is ongoing to finalise the Water Management Plan for the early works program and to progress the necessary approvals and permits that are required to commence the development of an operating underground mine and associated infrastructure at the Project(22).

The latest drilling results for the Havieron Project are included in the December 2020 Quarterly Exploration Report which was also released today.

Wafi-Golpu, Papua New Guinea

In December 2020, following a rigorous environmental impact assessment, the Papua New Guinean Conservation and Environment Protection Authority approved, and the Director of Environment issued, the Environment Permit for the Wafi-Golpu Project. The Environment Permit is required under the Papua New Guinean Environment Act and is a pre-requisite for the grant of a Special Mining Lease under the Mining Act.

Newcrest, together with its WGJV partner Harmony, looks forward to re-engaging with the State of Papua New Guinea and progressing discussions on the Special Mining Lease for the Wafi-Golpu Project.

Molybdenum Plant, Cadia, Australia

The Molybdenum Plant is on track to be fully commissioned in the fourth quarter of FY21. The Molybdenum Plant is expected to deliver an additional revenue stream for Cadia in the form of a molybdenum concentrate which will be recognised as a by-product credit to AISC.

Exploration

See the separately released “Quarterly Exploration Report” for the December 2020 quarter.

COVID-19 Update

To date, Newcrest has not experienced any material COVID-19 related disruptions to its operations or to the supply of goods and services.

Newcrest is managing a number of positive COVID-19 cases at its Red Chris mine in British Columbia and on Lihir Island, Papua New Guinea. Comprehensive testing, quarantine and precautionary contact tracing procedures continue to be enforced across all Newcrest sites with the cases identified to date at Lihir and Red Chris being largely asymptomatic or presenting minor symptoms.

The Lihir and Red Chris operations remain unaffected by the positive cases with strict hygiene, social distancing and other COVID-19 management protocols in place. As previously highlighted, all of Newcrest’s operations have business continuity plans and contingencies in place to minimise disruptions to the operations in the event of a significant number of operational employees and/or contractors contracting the virus. It is expected that these plans will enable the operations to continue producing in line with the production schedule, and if there are any material impacts, Newcrest will inform the market in line with its continuous disclosure obligations.

Costs associated with managing COVID risks in FY21 are now expected to be higher than anticipated at the start of the year due to more extensive testing, longer quarantining periods, roster and other labour costs, and other preventative actions. This has resulted in costs associated with managing COVID of approximately $30 million in the first half to end December 2020. The full year estimate is expected to be in the order of $60-70 million, up from the original estimate of $30-40 million.

Corporate

Community Support Fund

Newcrest’s A$20 million Community Support Fund strives to help its host communities in Papua New Guinea, Australia, Canada (British Columbia) and Ecuador cope with the challenges associated with COVID-19. A number of initiatives, ranging from immediate health assistance to livelihood restoration and economic recovery, have been funded to date.

Newcrest continues to work with its partners, host governments, communities and Indigenous Peoples to prioritise and deliver programs under the Fund in the most effective manner.

Toronto Stock Exchange Listing

On 13 October 2020, Newcrest listed its common shares on the Toronto Stock Exchange (TSX) under the symbol “NCM”. Newcrest retains its primary listing on the Australian Securities Exchange and its secondary listing on PNGX Markets. Newcrest’s listing on the TSX supports its pursuit of growth in the Americas following the 70% acquisition of the Red Chris mine in Canada, its investments in Ecuador and its expanding portfolio of exciting exploration and early stage entry prospects in the Americas.

Modern Slavery Statement

On 21 December 2020, Newcrest submitted its first Modern Slavery Statement to the Australian Department of Home Affairs in compliance with the 2018 Australian Modern Slavery Act. The Report sets out Newcrest’s public commitments to assess and address modern slavery risks in its global operations and supply chains, including due diligence and remediation processes. Newcrest’s Modern Slavery statement can be located within the Corporate Governance section of its website (www.newcrest.com).

Sustainability Report

On4 November 2020, Newcrest released its 2020 Sustainability Report which outlines Newcrest’s performance against its public sustainability targets for FY20 together with its expanded suite of sustainability targets for FY21. Newcrest’s Sustainability Report for FY20 can be located within the Sustainability section of its website (www.newcrest.com).

Interactive Analyst CentreTM

Newcrest’s financial and operational information can now be viewed via the Interactive Analyst CentreTMwhich is locatedunder the Investor tab on Newcrest’s website (www.newcrest.com). This interactive tool allows users to chart and export Newcrest’s current and historical results for further analysis.

Sandeep Biswas

Managing Director and Chief Executive Officer

Gold Production Summary

| December 2020 Quarter | Mine Production Tonnes (000’s)(23) | Tonnes Treated (000’s) | Head Grade (g/t Au) | Gold Recovery (%) | Gold Production (oz) | Gold Sales (oz) | All-In Sustaining Cost ($/oz)(2) |

| Cadia East Panel Cave 1 | 763 | ||||||

| Cadia East Panel Cave 2 | 6,304 | ||||||

| Cadia East Panel Cave 2-3 | 284 | ||||||

| Cadia(24) | 7,352 | 8,246 | 0.95 | 77.2 | 194,088 | 194,183 | (6) |

| Telfer Open Pit | 11,051 | 3,502 | 0.84 | 75.3 | 70,774 | ||

| Telfer Underground | 611 | 579 | 1.52 | 85.0 | 23,775 | ||

| Telfer Dump Leach | 4,305 | ||||||

| Telfer | 11,662 | 4,081 | 0.94 | 77.5 | 98,855 | 87,992 | 1,560 |

| Lihir | 7,326 | 3,691 | 2.27 | 74.2 | 200,173 | 170,308 | 1,438 |

| Red Chris | 5,508 | 1,530 | 0.42 | 55.5 | 11,375 | 12,641 | 3,278 |

| Fruta del Norte(25) | 30,986 | 30,986 | 810 | ||||

| Total | 31,848 | 17,549 | 1.18 | 75.4 | 535,477 | 496,110 | 968 |

All figures are shown at 100%, except for Red Chris which is shown at Newcrest’s 70% share and Fruta del Norte which is shown at Newcrest’s 32% attributable share through its 32% equity interest in Lundin Gold Inc.

Copper Production Summary

| December 2020 Quarter | Copper Grade (%) | Copper Recovery (%) | Concentrate Produced (tonnes) | Metal Production (tonnes) |

| Cadia | 0.39 | 82.1 | 112,087 | 26,643 |

| Telfer Open Pit | 0.06 | 52.8 | 12,676 | 1,050 |

| Telfer Underground | 0.27 | 88.2 | 13,144 | 1,393 |

| Telfer | 0.09 | 68.5 | 25,820 | 2,443 |

| Red Chris | 0.45 | 79.6 | 24,922 | 5,471 |

| Total | 0.29 | 80.6 | 162,829 | 34,557 |

All figures are shown at 100%, except for Red Chris which is shown at Newcrest’s 70% share.

Silver Production Summary

| December 2020 Quarter | Tonnes Treated (000’s) | Silver Production (oz) |

| Cadia | 8,246 | 167,864 |

| Telfer | 4,081 | 28,047 |

| Lihir | 3,691 | 10,126 |

| Red Chris | 1,530 | 24,733 |

| Total | 17,549 | 230,769 |

All figures are shown at 100%, except for Red Chris which is shown at Newcrest 70% share.

All-In Sustaining Cost – December 2020 Quarter

| 3 Months to 31 December 2020 | |||||||

| Units | Cadia | Telfer | Lihir | Red Chris | Corp/ Other | Group(26) | |

| Gold Produced | oz | 194,088 | 98,855 | 200,173 | 11,375 | – | 504,491 |

| Mining | $/oz prod. | 166 | 779 | 236 | 1,951 | – | 355 |

| Milling | $/oz prod. | 306 | 433 | 456 | 1,154 | – | 409 |

| Administration and other | $/oz prod. | 111 | 179 | 314 | 1,340 | – | 233 |

| Lease adjustments | $/oz prod | (3) | (24) | (6) | – | – | (8) |

| Third party smelting, refining and transporting costs(27) | $/oz prod. | 170 | 100 | 3 | 732 | – | 102 |

| Royalties | $/oz prod. | 102 | 53 | 44 | 68 | – | 69 |

| By-product credits | $/oz prod. | (1,014) | (167) | (1) | (3,797) | – | (509) |

| Ore inventory adjustments(28) | $/oz prod. | 25 | (35) | 83 | 87 | – | 37 |

| Production stripping adjustments(28) | $/oz prod. | – | – | (131) | (417) | – | (61) |

| AOD adjustments(28) | $/oz prod. | – | 21 | – | – | – | 4 |

| Net Cash Costs | $/oz prod. | (137) | 1,339 | 998 | 1,118 | – | 631 |

| Gold Sold | oz | 194,183 | 87,992 | 170,308 | 12,641 | – | 465,125 |

| Adjusted operating costs(29) | $/oz sold | (131) | 1,355 | 1,034 | 1,263 | – | 615 |

| Corporate general & administrative costs(30),(31) | $/oz sold | – | – | – | – | 57 | 57 |

| Reclamation and remediation costs | $/oz sold | 5 | 5 | 12 | 56 | – | 9 |

| Production stripping | $/oz sold | – | – | 154 | 375 | – | 67 |

| Advanced operating development | $/oz sold | – | (24) | – | – | – | (5) |

| Capital expenditure (sustaining) | $/oz sold | 115 | 164 | 228 | 1,580 | 14 | 219 |

| Exploration (sustaining) | $/oz sold | 2 | 19 | 2 | (49) | – | 4 |

| Leases (sustaining) | $/oz sold | 3 | 41 | 8 | 53 | – | 13 |

| All-In Sustaining Cost | $/oz sold | (6) | 1,560 | 1,438 | 3,278 | 71 | 979 |

| Growth and development costs(31) | $/oz sold | – | – | – | – | 7 | 7 |

| Capital expenditure (non-sustaining)(32) | $/oz sold | 568 | – | 109 | 302 | 11 | 297 |

| Exploration (non-sustaining) | $/oz sold | – | 2 | – | 409 | 52 | 64 |

| Leases (non-sustaining) | $/oz sold | 6 | – | – | – | – | 2 |

| All-In Cost | $/oz sold | 568 | 1,562 | 1,547 | 3,989 | 141 | 1,349 |

| Depreciation and amortisation(33) | $/oz sold | 259 | 250 | 374 | 1,178 | 12 | 336 |

All figures are shown at 100%, except for Red Chris which is shown at 70%. AISC and AIC may not calculate based on amounts presented in these tables due to rounding.

All-In Sustaining Cost – Six months to 31 December 2020

| 6 Months to 31 December 2020 | |||||||

| Units | Cadia | Telfer | Lihir | Red Chris | Corp/ Other | Group | |

| Gold Produced | oz | 390,592 | 185,307 | 377,510 | 24,012 | – | 977,421(34) |

| Mining | $/oz prod. | 173 | 848 | 247 | 1,635 | – | 365 |

| Milling | $/oz prod. | 312 | 463 | 545 | 1,060 | – | 449 |

| Administration and other | $/oz prod. | 102 | 194 | 277 | 1,223 | – | 215 |

| Lease Adjustments | $/oz prod | (3) | (28) | (5) | – | – | (9) |

| Third party smelting, refining and transporting costs(35) | $/oz prod. | 159 | 113 | 3 | 649 | – | 102 |

| Royalties | $/oz prod. | 97 | 52 | 47 | 64 | – | 69 |

| By-product credits | $/oz prod. | (927) | (171) | (1) | (3,623) | – | (493) |

| Ore inventory adjustments(36) | $/oz prod. | 12 | (15) | 79 | 93 | – | 35 |

| Production stripping adjustments(36) | $/oz prod. | – | – | (151) | (789) | – | (77) |

| AOD adjustments(36) | $/oz prod. | – | 10 | – | – | – | 2 |

| Net Cash Costs | $/oz prod. | (75) | 1,466 | 1,041 | 312 | – | 658 |

| Gold Sold | oz | 389,329 | 173,089 | 381,139 | 24,475 | – | 968,032 |

| Adjusted operating costs(37) | $/oz sold | (79) | 1,478 | 1,031 | 276 | – | 645 |

| Corporate general & administrative costs(38),(39) | $/oz sold | – | – | – | – | 46 | 46 |

| Reclamation and remediation costs | $/oz sold | 5 | 5 | 10 | 64 | – | 9 |

| Production stripping | $/oz sold | – | – | 150 | 774 | – | 78 |

| Advanced operating development | $/oz sold | – | (11) | – | – | – | (2) |

| Capital expenditure (sustaining) | $/oz sold | 122 | 146 | 155 | 1,809 | 10 | 192 |

| Exploration (sustaining) | $/oz sold | 3 | 14 | 1 | – | – | 4 |

| Leases (sustaining) | $/oz sold | 3 | 44 | 5 | 38 | – | 12 |

| All-In Sustaining Cost | $/oz sold | 54 | 1,676 | 1,352 | 2,961 | 56 | 984 |

| Growth and development costs(39) | $/oz sold | – | – | – | – | 6 | 6 |

| Capital expenditure (non-sustaining)(40) | $/oz sold | 524 | – | 76 | 290 | 9 | 257 |

| Exploration (non-sustaining) | $/oz sold | – | 3 | – | 382 | 50 | 61 |

| Leases (non-sustaining) | $/oz sold | 6 | – | – | – | – | 2 |

| All-In Cost | $/oz sold | 584 | 1,679 | 1,428 | 3,633 | 121 | 1,310 |

| Depreciation and amortisation(41) | $/oz sold | 252 | 253 | 363 | 1,163 | 12 | 330 |

All figures are shown at 100%, except for Red Chris which is shown at 70%. AISC and AIC may not calculate based on amounts presented in these tables due to rounding.

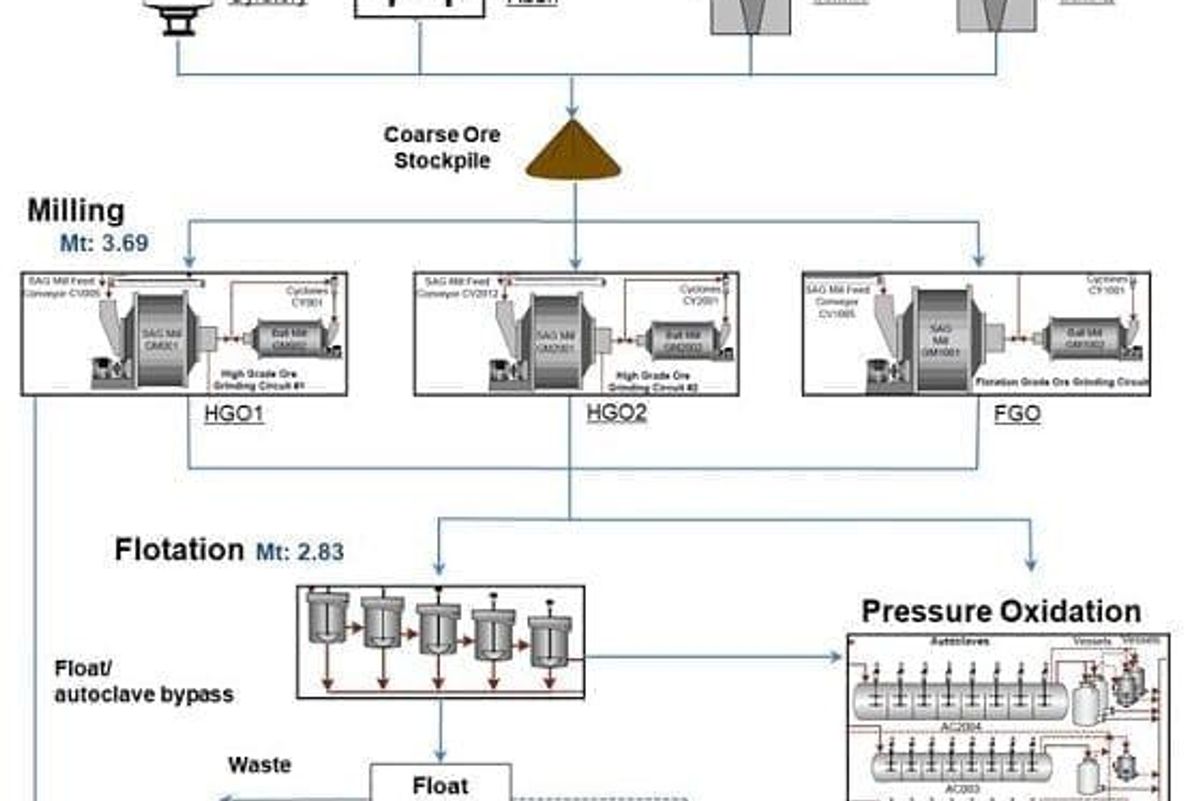

Simplified Lihir Pit Material Flow – December 2020 Quarter

To view an enhanced version of this graphic, please visit:

https://orders.newsfilecorp.com/files/7614/73004_newcrest_image1.jpg

Simplified Lihir Process Flow – December 2020 Quarter

To view an enhanced version of this graphic, please visit:

https://orders.newsfilecorp.com/files/7614/73004_newcrest_image2.jpg

Corporate Information

Board

| Peter Hay | Non-Executive Chairman |

| Sandeep Biswas | Managing Director and CEO |

| Gerard Bond | Finance Director and CFO |

| Philip Aiken AM | Non-Executive Director |

| Roger Higgins | Non-Executive Director |

| Sally-Anne Layman | Non-Executive Director |

| Vickki McFadden | Non-Executive Director |

| Peter Tomsett | Non-Executive Director |

Company Secretaries

Maria Sanz Perez and Claire Hannon

Registered & Principal Office

Level 8, 600 St Kilda Road, Melbourne, Victoria, Australia 3004

Telephone: +61 (0)3 9522 5333

Facsimile: +61 (0)3 9522 5500

Email: corporateaffairs@newcrest.com.au

Website: www.newcrest.com

Stock Exchange Listings

| Australian Securities Exchange | (Ticker NCM) |

| Toronto Stock Exchange | (Ticker NCM) |

| PNGX Markets Limited | (Ticker NCM) |

| New York ADR’s | (Ticker NCMGY) |

Forward Shareholder Enquiries to:

Australia:

Link Market Services

Tower 4, 727 Collins Street

Docklands, Victoria, 3008

Australia

Telephone: 1300 554 474

+61 (0)2 8280 7111

Facsimile: +61 (0)2 9287 0303

Email: registrars@linkmarketservices.com.au

Website: www.linkmarketservices.com.au

Canada:

AST Trust Company (Canada)

P.O. Box 700, Station B

Montreal, Quebec, H3B 3K3

Canada

+1 800 387 0825

inquiries@astfinancial.com

www.astfinancial.com

Substantial Shareholder(s)(42) at 31 December 2020

| BlackRock Group | 10.2% |

| Allan Gray / Orbis Group | 9.9% |

| Van Eck Associates Corporation | 5.1% |

| The Vanguard Group | 5.0% |

Issued Share Capital

At 31 December 2020, Newcrest’s issued capital was 816,556,534 ordinary shares.

Quarterly Share Price Activity

| High | Low | Close | |

| A$ | A$ | A$ | |

| Oct – Dec 2020 | 32.00 | 25.78 | 25.78 |

Forward Looking Statements

This document includes forward looking statements and forward looking information within the meaning of securities laws of applicable jurisdictions. Forward looking statements can generally be identified by the use of words such as “may”, “will”, “expect”, “intend”, “plan”, “estimate”, “anticipate”, “believe”, “continue”, “objectives”, “targets”, “outlook” and “guidance”, or other similar words and may include, without limitation, statements regarding estimated reserves and resources, certain plans, strategies, aspirations and objectives of management, anticipated production, study or construction dates, expected costs, cash flow or production outputs and anticipated productive lives of projects and mines. Newcrest continues to distinguish between outlook and guidance. Guidance statements relate to the current financial year. Outlook statements relate to years subsequent to the current financial year.

These forward looking statements involve known and unknown risks, uncertainties and other factors that may cause Newcrest’s actual results, performance and achievements or industry results to differ materially from any future results, performance or achievements, or industry results, expressed or implied by these forward-looking statements. Relevant factors may include, but are not limited to, changes in commodity prices, foreign exchange fluctuations and general economic conditions, increased costs and demand for production inputs, the speculative nature of exploration and project development, including the risks of obtaining necessary licences and permits and diminishing quantities or grades of reserves, political and social risks, changes to the regulatory framework within which Newcrest operates or may in the future operate, environmental conditions including extreme weather conditions, recruitment and retention of personnel, industrial relations issues and litigation. For further information as to the risks which may impact on Newcrest’s results and performance, please see the risk factors included in the Annual Information Form dated 13 October 2020 lodged with ASX and SEDAR.

Forward looking statements are based on Newcrest’s good faith assumptions as to the financial, market, regulatory and other relevant environments that will exist and affect Newcrest’s business and operations in the future. Newcrest does not give any assurance that the assumptions will prove to be correct. There may be other factors that could cause actual results or events not to be as anticipated, and many events are beyond the reasonable control of Newcrest. Readers are cautioned not to place undue reliance on forward looking statements, particularly in the current economic climate with the significant volatility, uncertainty and disruption caused by the COVID-19 pandemic. Forward looking statements in this document speak only at the date of issue. Except as required by applicable laws or regulations, Newcrest does not undertake any obligation to publicly update or revise any of the forward looking statements or to advise of any change in assumptions on which any such statement is based.

Non-IFRS Financial Information

Newcrest results are reported under International Financial Reporting Standards (IFRS). This document includes non-IFRS financial information within the meaning of ASIC Regulatory Guide 230: ‘Disclosing non-IFRS financial information’ published by ASIC and within the meaning of Canadian Securities Administrators Staff Notice 52-306 – Non-GAAP Financial Measures. Such information includes All-In Sustaining Cost (AISC) and All-In Cost (AIC) as per updated World Gold Council Guidance Note on Non-GAAP Metrics released in November 2018. AISC will vary from period to period as a result of various factors including production performance, timing of sales and the level of sustaining capital and the relative contribution of each asset. AISC Margin reflects the average realised gold price less AISC per ounce sold.

These measures are used internally by Newcrest management to assess the performance of the business and make decisions on the allocation of resources and are included in this document to provide greater understanding of the underlying performance of Newcrest’s operations. The non-IFRS information has not been subject to audit or review by Newcrest’s external auditor and should be used in addition to IFRS information. Such non-IFRS information/non-GAAP measures do not have a standardised meaning prescribed by IFRS and may be calculated differently by other companies. Although Newcrest believes these non-IFRS/non-GAAP financial measures provide useful information to investors in measuring the financial performance and condition of its business, investors are cautioned not to place undue reliance on any non-IFRS financial information/non-GAAP financial measures included in this document. When reviewing business performance, this non-IFRS information should be used in addition to, and not as a replacement of, measures prepared in accordance with IFRS, available on Newcrest’s website and the ASX and SEDAR platforms.

Technical and Scientific Information

The technical and scientific information contained in this document relating to Wafi-Golpu and Lihir was reviewed and approved by Craig Jones, Newcrest’s Chief Operating Officer PNG, FAusIMM and a Qualified Person as defined in National Instrument

43-101 – Standards of Disclosure for Mineral Projects (NI 43-101). The technical and scientific information contained in this document relating to Cadia was reviewed and approved by Philip Stephenson, Newcrest’s Chief Operating Officer Australia and Americas, FAusIMM and a Qualified Person as defined in NI 43-101.

Competent Persons’ Statement

The information in this document that relates to Mineral Resources has been extracted from the release titled “Initial Inferred Mineral Resource estimate for Havieron of 3.4Moz of gold and 160Kt of copper” dated 10 December 2020 and which is available to view at www.asx.com.au under the code “NCM” (the original release) and on Newcrest’s SEDAR profile. Newcrest confirms that it is not aware of any new information or data that materially affects the information included in the original release and that all material assumptions and technical parameters underpinning the estimates in the original release continue to apply and have not materially changed. Newcrest confirms that the form and context in which the competent persons’ findings are presented have not been materially modified from the original release.

Authorised by the Newcrest Disclosure Committee

For further information please contact

Investor Enquiries

Tom Dixon

+61 3 9522 5570

+61 450 541 389

Tom.Dixon@newcrest.com.au

Ben Lovick

+61 3 9522 5334

+61 407 269 478

Ben.Lovick@newcrest.com.au

North American Investor Enquiries

Ryan Skaleskog

+1 866 396 0242

+61 403 435 222

Ryan.Skaleskog@newcrest.com.au

Media Enquiries

Tom Dixon

+61 3 9522 5570

+61 450 541 389

Tom.Dixon@newcrest.com.au

Annie Lawson

+61 3 9522 5750

+61 409 869 986

Annie.Lawson@newcrest.com.au

This information is available on our website at www.newcrest.com

Appendix

Reconciliation of Newcrest’s operational performance including its 32% attributable share of Fruta del Norte through its 32% equity interest in Lundin Gold Inc.

| Gold production | Metric | Dec 2020 Qtr | Sep 2020 Qtr | YTD FY21 |

| Gold production – Newcrest operations | oz | 504,491 | 472,929 | 977,421 |

| Gold production – Fruta del Norte (32%)(43) | oz | 30,986 | 30,160 | 61,146 |

| Gold production | oz | 535,477 | 503,089 | 1,038,566 |

| All-In Sustaining Cost | Metric | Dec 2020 Qtr | Sep 2020 Qtr | YTD FY21 |

| All-in Sustaining Cost – Newcrest operations | $m | 455 | 498 | 953 |

| All-in Sustaining Cost – Fruta del Norte (32%)(43),(44) | $m | 25 | 14 | 39 |

| All-In Sustaining Cost | $m | 480 | 512 | 992 |

| Gold ounces sold – Newcrest operations | oz | 465,125 | 502,907 | 968,032 |

| Gold ounces sold – Fruta del Norte (32%)(43),(44) | oz | 30,986 | 19,891 | 50,877 |

| Total gold ounces sold | oz | 496,110 | 522,798 | 1,018,908 |

| All-In Sustaining Cost – Newcrest operations | $/oz | 979 | 990 | 984 |

| All-In Sustaining – Fruta del Norte (32%)(43),(44) | $oz | 810 | 728 | 778 |

| All-In Sustaining Cost | $/oz | 968 | 980 | 974 |

| All-In Sustaining Margin | Metric | Dec 2020 Qtr | Sep 2020 Qtr | YTD FY21 |

| Realised gold price(45) | $/oz | 1,815 | 1,837 | 1,826 |

| All-In Sustaining Cost – Newcrest operations | $/oz | 979 | 990 | 984 |

| All-In Sustaining Cost margin | $/oz | 836 | 847 | 842 |

1See information under heading “Non-IFRS Financial Information” on Page 18 of this report for further information.

2Includes 31koz andanestimated reduction of $11/oz based on Newcrest’s 32% attributable shareof Fruta del Norte. Refer to the Appendix for calculation andfurther details.

3Newcrest’s AISC margin has been determined by deducting the All-In Sustaining Cost attributable to Newcrest’s operations from Newcrest’s realised gold price.Refer to the Appendix for details.

4The initial Inferred Mineral Resource estimate is presented on a 100% basis. As announced on 30 November 2020, Newcrest has now met the Stage 3 expenditure requirement (US$45 million) and is entitled to earn an additional 20% joint venture interestin addition to its existing 40% interest, resulting in an overall joint venture interest of 60% (Greatland Gold 40%).

5Per tonne of ore treated and compared to a baseline of FY18 emissions. Subject to market and operating conditions in respect of Cadia and the Rye ParkWind Farm

6Total Recordable Injury Frequency Rate (injuries per million hours). TRIFR for FY20 includes safety results for Red Chris from acquisition.

7Due to the negligible impact of Fruta del Norte on Newcrest’s Group AISC for FY20 it has been excluded from the FY20 calculation.

8AISC for the period ending 31 December 2019 has been restated to reflect adjustments applied to Red Chris following the completion of acquisition and year end processes.

9Realised metal prices are the US$ spot prices at the time of sale per unit of metal sold (net of Telfer gold production hedges), excluding deductions related to treatment and refining charges and the impact of price related finalisations for metals in concentrate. The realised price for the September and December quarters and for FY20 and FY21 has been calculated using sales ounces generated by Newcrest’s operations only (i.e. excluding Fruta del Norte).

10The achievement of guidance is subject to market and operating conditions. Newcrest’s guidance for Fruta del Norte is an annualised figure based on Lundin Gold Inc’s production guidance for 1 July 2020 to 31 December 2020. See Appendix for further details.

11The figures shown represent Newcrest’s 70% share of the unincorporated Red Chris JV.Production outcomes for FY20 are reported from the date of acquisition (15 August 2019).

12 The figures shown represent 100%. Prior to the divestment on 4 March 2020, Newcrest owned 75% of Gosowong through its holding in PT Nusa Halmahera Minerals, an incorporated joint venture. Production and financial outcomesfor FY20 represent Newcrest’s period of ownership to the divestment date.

13The figures shown represent Newcrest’s 32%attributable share, through its 32% equity interest in Lundin Gold Inc.

14From Newcrest’s operations only and does not include Newcrest’s 32% attributable share of Fruta del Norte through its 32%equityinterest in Lundin Gold Inc.

15Subsequent to the release of the December 2019 Quarterly Report, an audit adjustment was applied which reduced gold sales by ~6koz, copper sales by ~49kt and AISC by $5/oz respectively.

16Per tonne of ore treated and compared to a baseline of FY18 emissions. Subject to market and operating conditions in respect of Cadia and the Rye Park Wind Farm.

17 AISC margin calculated with reference to the Group average realised gold price.

18The figures shown represent Newcrest’s 70% shareof the unincorporated Red Chris JV. Productionand financial outcomesfor FY20 are reported fromthe date of acquisition (15 August 2019).

19AISC reported for the six month period to 31 December 2019 has been restated to reflect adjustments applied following the completion of acquisition and year end processes.

20The initial Inferred Mineral Resource estimate is presented on a 100% basis. As announced on 30 November 2020, Newcrest has now met the Stage 3 expenditure requirement (US$45 million) and is entitled to earn an additional 20% joint venture interest in addition to its existing 40% interest, resulting in an overall joint venture interest of 60% (Greatland Gold 40%).

21 On a 100% basis and converted to US$ using an exchange rate of 0.77, which was the spot rate on the date of the initial announcement..

22 In addition, the development of any underground mine at the Havieron Project will also be subject to the completion of a successful exploration program and further studies, market and operating conditions, Board approvals, and a positive decision to mine.

23 Mine production for open pit and underground includes ore and waste.

24 Includes development tonnesfrom the Cadia East PC2-3 project. Costs associated with this production were capitalised and are not included in the AISC calculation in this report.

25Due to timing of Lundin Gold’s December quarterly report, Newcrest has estimated its 32% attributable share, through its 32% equity interest in Lundin Gold Inc,of Fruta del Norte’s All-In Sustaining Cost for the quarter. For the purposes of All-In Sustaining Cost, Newcrest has assumed that production is equal to sales. Refer to the Appendix for further details.

26Group AISC is for Newcrest’s operations only and does not include Newcrest’s 32% attributable share of Fruta del Norte.

27 Includes deductions related to treatment and refining charges for metals in concentrate

28 Represents adjustment for ore inventory movements, removal of production stripping costs and movement in Advanced Operating Development costs

29 Adjusted operating costs represents net cash costs adjusted for finished goods inventory movements, divided by ounces sold

30 Corporate general & administrative costs includes share-based remuneration

31 Costs of this nature were previously reported within Corporate Costs. In accordance with the updated World Gold Council guidance, growth and development costs are now presented in AIC.

32Represents spend on major projects that are designed to increase the net present value of the mine are not related to current production. Significant projects in the current period include key expansion projects at Cadia (including PC2-3 developmentand the molybdenum plant)and Lihir (Seepage Barrier feasibilitystudy, front end recovery and HV upgrade).

33 Depreciation and amortisation of mine site assets is determined on the basis of the lesser of the asset’s useful economic life and the life of the mine.Life-of-mine assets are depreciated according to units of production and the remainder on a straight line basis. Depreciation and amortisation does not form part of All-In Sustaining Cost or All-in Cost with the exception of amortisation on reclamation and remediation (rehabilitation) assets

34Group AISC is for Newcrest’s operations only and does not include Newcrest’s 32% attributable share of Fruta del Norte.

35 Includes deductions related to treatment and refining charges for metals in concentrate

36 Represents adjustment for ore inventory movements, removal of production stripping costs and movement in Advanced Operating Development costs

37 Adjusted operating costs represents net cash costs adjusted for finished goods inventory movements, divided by ounces sold

38 Corporate general & administrative costs includes share-based remuneration

39 Costs of this nature were previously reported within Corporate Costs. In accordance with the updated World Gold Council guidance, growth and development costs are now presented in AIC.

40Represents spend on major projects that are designed to increase the net present value of the mine are not related to current production. Significant projects in the year include key expansion projects at Cadia (including PC2-3 feasibility study and the molybdenum plant) and Lihir (Seepage Barrier feasibility study, front end recovery and HV upgrade).

41 Depreciation and amortisation of mine site assets is determined on the basis of the lesser of the asset’s useful economic life and the life of the mine.Life-of-mine assets are depreciated according to units of production and the remainder on a straight line basis. Depreciation and amortisation does not form part of All-In Sustaining Cost or All-in Cost with the exception of amortisation on reclamation and remediation (rehabilitation) assets.

42As notified to Newcrest under section 671B of the Corporations Act 2001

43The All-In Sustaining Cost and gold ounces sold outcomes for Fruta del Norte for the September 2020 quarter have been restated following the release of Lundin Gold’s September quarterly report on 9 November 2020. Newcrest’s All-In Sustaining Cost outcome of $980/oz for the September quarter remains unchanged.

44 Due to timing of Lundin Gold’s December quarterly report, Newcrest has estimated its 32% attributable share, through its 32% equity interest in Lundin Gold Inc, of Fruta del Norte’s All-In Sustaining Cost for the quarter. The estimate for All-In Sustaining Cost was derived by taking the mid-point of Newcrest’s guidance range of $810/oz (at Newcrest’s 32% attributable share). For the purposes of AISC, Newcrest has assumed that production is equal to sales. A true-up will be made in the March quarter once the outcomes for the December quarter are known. Newcrest’s guidance with respect to the gold production of Fruta del Norte is based on Lundin Gold’s July to December 2020 guidance of 150,000 – 170,000 ounces which has been annualised on the assumption that production levels will be same for the January to June 2021 period (presented at 32% and rounded to nearest 5koz). With respect to Newcrest’s guidance for AISC, the dollar million range has been derived by multiplying the low end of annualised production of Newcrest’s guidance by the high end of Lundin Gold’s July – December 2020 AISC guidance of $770/oz – $850/oz, and the high end of annualised production of Newcrest’s guidance multiplied by the low end of the same AISC guidance range.

45Realised metal prices are the US$ spot prices at the time of sale per unit of metal sold (net of Telfer production hedges), excluding deductions related to treatment and refining charges and the impact of price related finalisations for metals in concentrate. The realised price for the September and December quarters and for FY21 has been calculated using sales ounces generated by Newcrest’s operations only (i.e. excluding Fruta del Norte).

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/73004