- WORLD EDITIONAustraliaNorth AmericaWorld

Investing News NetworkYour trusted source for investing success

- Lithium Outlook

- Oil and Gas Outlook

- Gold Outlook Report

- Uranium Outlook

- Rare Earths Outlook

- All Outlook Reports

- Top Generative AI Stocks

- Top EV Stocks

- Biggest AI Companies

- Biggest Blockchain Stocks

- Biggest Cryptocurrency-mining Stocks

- Biggest Cybersecurity Companies

- Biggest Robotics Companies

- Biggest Social Media Companies

- Biggest Technology ETFs

- Artificial Intellgience ETFs

- Robotics ETFs

- Canadian Cryptocurrency ETFs

- Artificial Intelligence Outlook

- EV Outlook

- Cleantech Outlook

- Crypto Outlook

- Tech Outlook

- All Market Outlook Reports

- Cannabis Weekly Round-Up

- Top Alzheimer's Treatment Stocks

- Top Biotech Stocks

- Top Plant-based Food Stocks

- Biggest Cannabis Stocks

- Biggest Pharma Stocks

- Longevity Stocks to Watch

- Psychedelics Stocks to Watch

- Top Cobalt Stocks

- Small Biotech ETFs to Watch

- Top Life Science ETFs

- Biggest Pharmaceutical ETFs

- Life Science Outlook

- Biotech Outlook

- Cannabis Outlook

- Pharma Outlook

- Psychedelics Outlook

- All Market Outlook Reports

Premier1 Lithium

AI-based and data-driven approach to lithium exploration in Western Australia

Company Highlights

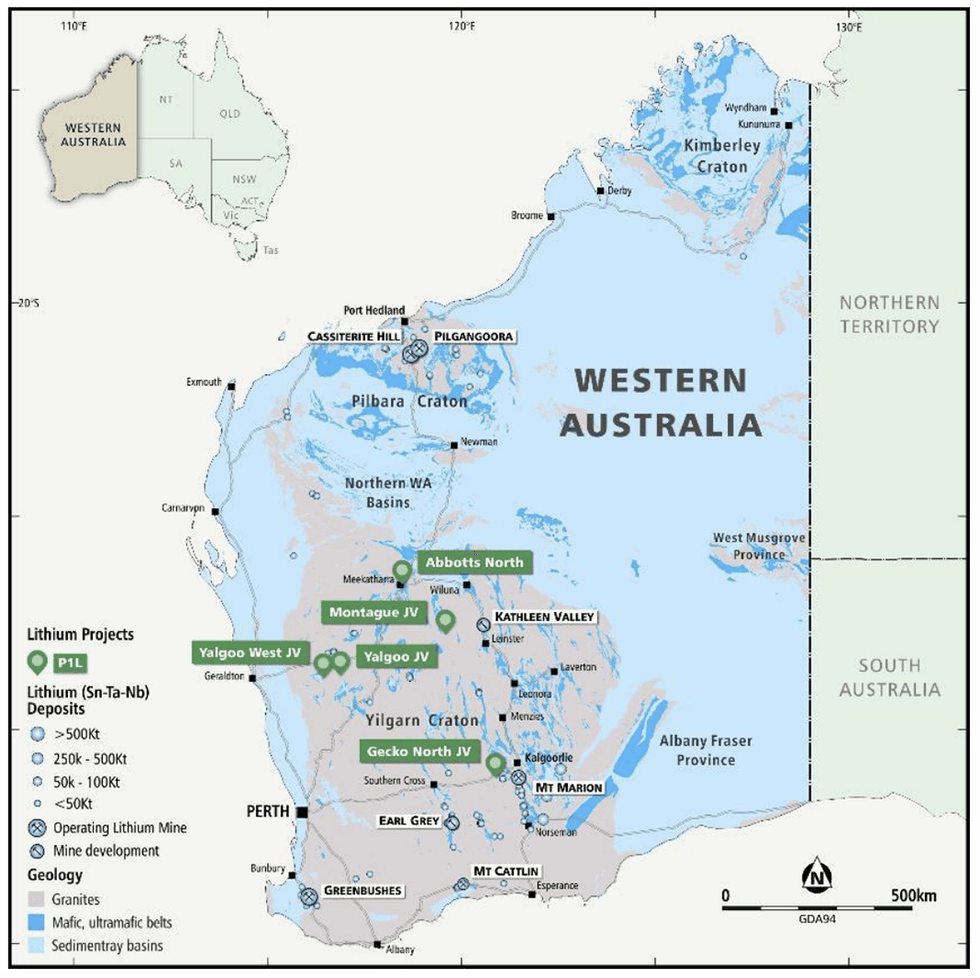

- Premier1 Lithium is focused on lithium exploration in Western Australia, one of the best jurisdictions in the world for hard rock lithium.

- The company was formed following the restructuring of SensOre Limited. SensOre demerged its non-core software and AI technology business, and the remaining company was rebranded as Premier1 Lithium to focus on the lithium business.

- The company holds a pipeline of promising lithium projects led by its wholly owned flagship project, Abbotts North, and three joint venture projects – Yalgoo and Yalgoo West, Montague and Gecko North.

- The company’s lithium prospects are selected using AI and machine learning. This data-driven approach allows Premier1 to prioritize resource allocation toward the most prospective targets.

- Premier1 is on track to commence a 2,000-meter RC drilling program at Abbotts North in February 2024. All the environmental and heritage approvals required for the drilling program have been received.

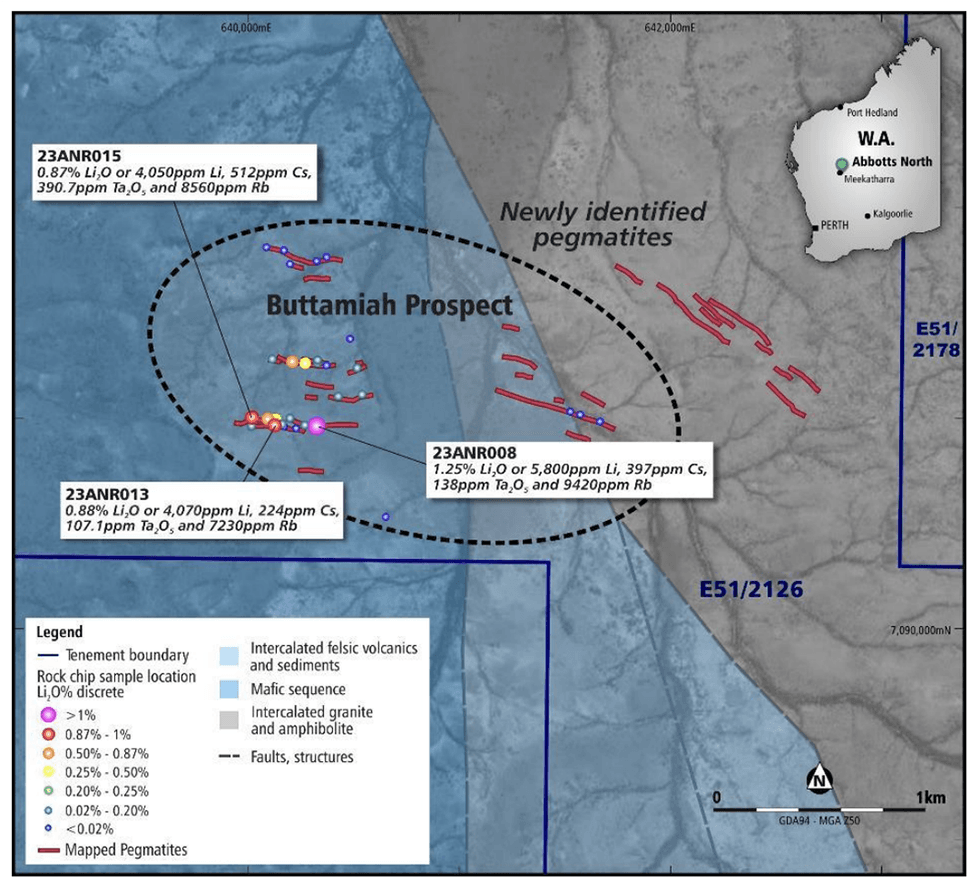

- The focus of the drilling program is on the Buttamiah Prospect within the Abbotts North Project, which is characterized by lithium-bearing pegmatite occurrences and has returned assays up to 1.25 percent lithium oxide at the surface.

- In addition to Abbotts North, Premier1 has planned extensive exploration work at its JV projects. This includes pegmatite mapping and sampling, as well as soil and auger geochemistry to delineate drill targets at Montague and Yalgoo beginning the second half of 2024.

- Premier1 Lithium offers investors an attractive way to benefit from the growing demand for lithium.

Overview

Premier1 Lithium (ASX:PLC) is an Australian company focused on lithium exploration in Western Australia. The company was formed following the restructuring of SensOre. SensOre demerged its non-core software and AI technology business and the remaining company was rebranded as Premier1 Lithium to focus on the lithium business.

Premier1 employs artificial intelligence and machine learning technology to choose its lithium prospects. Through a data-driven approach, the company can strategically allocate resources to prioritize the most promising targets.

Premier1 Lithium Investor Kit

- Corporate info

- Insights

- Growth strategies

- Upcoming projects

GET YOUR FREE INVESTOR KIT

Overview

Premier1 Lithium (ASX:PLC) is an Australian company focused on lithium exploration in Western Australia. The company was formed following the restructuring of SensOre. SensOre demerged its non-core software and AI technology business and the remaining company was rebranded as Premier1 Lithium to focus on the lithium business.

Premier1 employs artificial intelligence and machine learning technology to choose its lithium prospects. Through a data-driven approach, the company can strategically allocate resources to prioritize the most promising targets.

The company’s portfolio comprises one wholly-owned project and three other projects with joint venture (JV) partners. The wholly owned Abbotts North project is its flagship asset, with the Buttamiah Prospect as the primary area of focus. The Buttamiah Prospect is characterized by lithium-bearing pegmatite occurrences and has returned assays up to 1.25 percent lithium oxide at the surface.

The other three JV projects are: 1) Yalgoo and Yalgoo West Project, with JV partners Venture Minerals and Firetail; 2) Montague Project, with JV partner Gateway Mining; and 3) Gecko North Project, with JV partner LithGold.

Western Australia represents one of the best jurisdictions for lithium exploration. The state offers a stable investment environment supported by a transparent regulatory system, access to export markets, and minimal barriers to international trade. Archean cratons in the region are the most prospective and represent some of the world’s largest lithium-bearing pegmatite deposits. The company’s Abbotts North Project is in the Archean cratons making it a sought-after lithium asset.

According to the Office of the Chief Economist within the Department of Industry, Science and Resources, Western Australia is projected to possess around 10 percent of the global lithium hydroxide refining capacity by 2024. That projection is expected to further increase to over 20 percent of the global lithium refining capacity by 2028.

Lithium as a mineral is in great focus, given its application in batteries for electric vehicles. It represents the most in-demand metal required for the energy transition. The global shift away from fossil fuels is ongoing, which should fuel demand for lithium in the next decade. According to a report by the International Energy Agency, global battery and minerals supply chains must expand by 10 times to meet the demand in 2030. This should benefit lithium which remains a key battery ingredient.

Projections by mining giant Albemarle suggest that lithium demand will reach 3.7 million tons by 2030 driven by favorable government policies in many countries aimed at phasing out new internal combustion engine car sales. As the global demand for lithium continues to expand, Premier1’s exploration and development initiatives are well-timed, providing investors with an opportunity to participate in the swiftly growing lithium market.

Company Highlights

- Premier1 Lithium is focused on lithium exploration in Western Australia, one of the best jurisdictions in the world for hard rock lithium.

- The company was formed following the restructuring of SensOre Limited. SensOre demerged its non-core software and AI technology business, and the remaining company was rebranded as Premier1 Lithium to focus on the lithium business.

- The company holds a pipeline of promising lithium projects led by its wholly owned flagship project, Abbotts North, and three joint venture projects – Yalgoo and Yalgoo West, Montague and Gecko North.

- The company’s lithium prospects are selected using AI and machine learning. This data-driven approach allows Premier1 to prioritize resource allocation toward the most prospective targets.

- Premier1 is on track to commence a 2,000-meter RC drilling program at Abbotts North in February 2024. All the environmental and heritage approvals required for the drilling program have been received.

- The focus of the drilling program is on the Buttamiah Prospect within the Abbotts North Project, which is characterized by lithium-bearing pegmatite occurrences and has returned assays up to 1.25 percent lithium oxide at the surface.

- In addition to Abbotts North, Premier1 has planned extensive exploration work at its JV projects. This includes pegmatite mapping and sampling, as well as soil and auger geochemistry to delineate drill targets at Montague and Yalgoo beginning the second half of 2024.

- Premier1 Lithium offers investors an attractive way to benefit from the growing demand for lithium.

Key Projects

Abbotts North Project

Abbotts North is the company’s 100 percent-owned flagship lithium project. This project is situated in the Abbotts Greenstone Belt region, which has not been previously explored for lithium. The Buttamiah prospect, the key target area within the Abbotts North, has shown confirmed pegmatite occurrences that yield up to 1.25 percent lithium oxide at the surface.

Several parallel lithium-bearing pegmatites have been mapped and sampled at the Buttamiah Prospect. The individual pegmatites exhibit an average width ranging from 2 meters to 3 meters and can be followed along a strike length of up to 350 meters. The main Buttamiah Prospect extends over a total area of 1.5 kilometers.

Premier1 is on track to commence a 2,000-metre RC drilling program in February 2024, designed to test the depth and extent of the mineralized pegmatite field at the Buttamiah Prospect. All the environmental and heritage approvals required for the drilling program have been received.

Several additional priority targets have been identified at the Abbotts North Project following the completion of the initial phase of field mapping, rock chip sampling and soil geochemistry in December 2023. The soil survey results unveiled areas of interest with a geochemical structure similar to those observed over the primary Buttamiah Prospect. Subsequent fieldwork will be undertaken to evaluate these newly identified priority targets and plan for additional heritage clearance surveys.

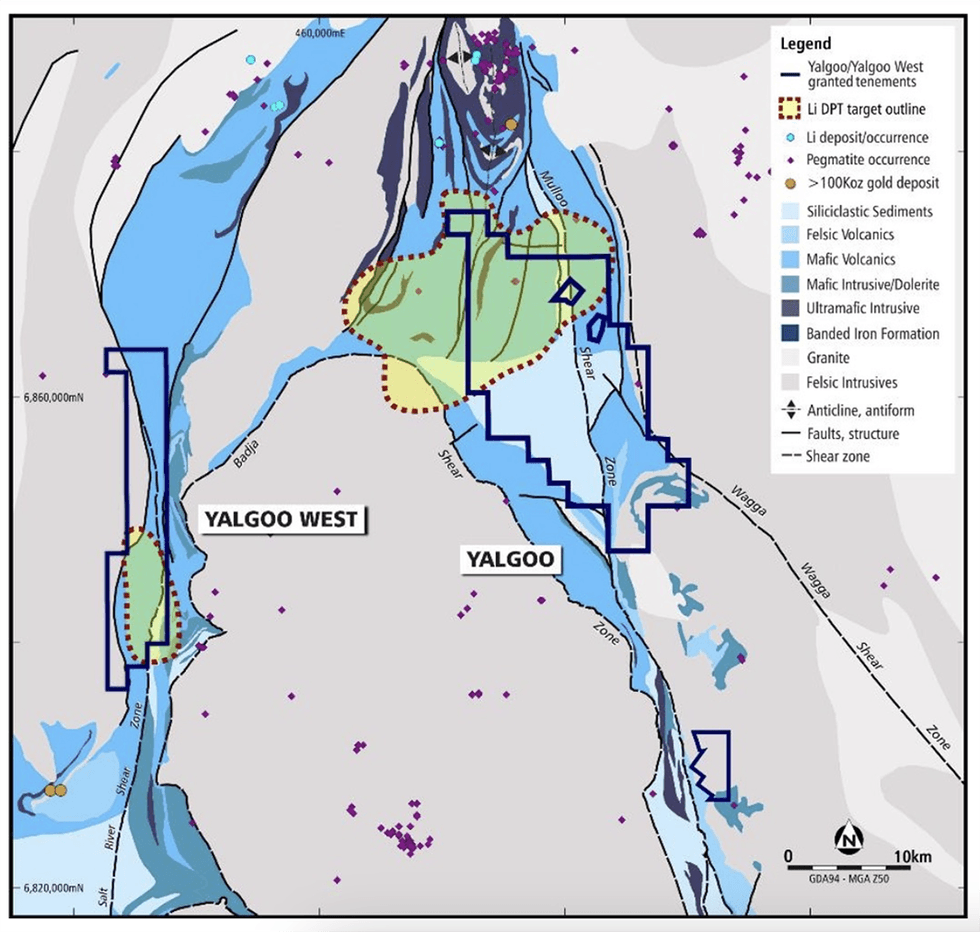

Yalgoo and Yalgoo West Project

Yalgoo and Yalgoo West are key projects in the company’s lithium portfolio. AI and machine learning were used to identify these projects as having significant potential for lithium. These assets are part of the Greenstone Belt region, which is underexplored. The greenstone belt is characterized by multiple phases of granitic intrusions, including known LCT pegmatites.

Premier1 can earn up to 70 percent of the lithium rights for the Yalgoo project from Venture Minerals and 80 percent of mineral rights (except rare earth elements) from Firetail Resources for the Yalgoo West project.

The land access approvals are in place and the company is planning extensive fieldwork, including pegmatite sampling, soil and auger geochemistry, to identify targets for initial drilling beginning H2 2024.

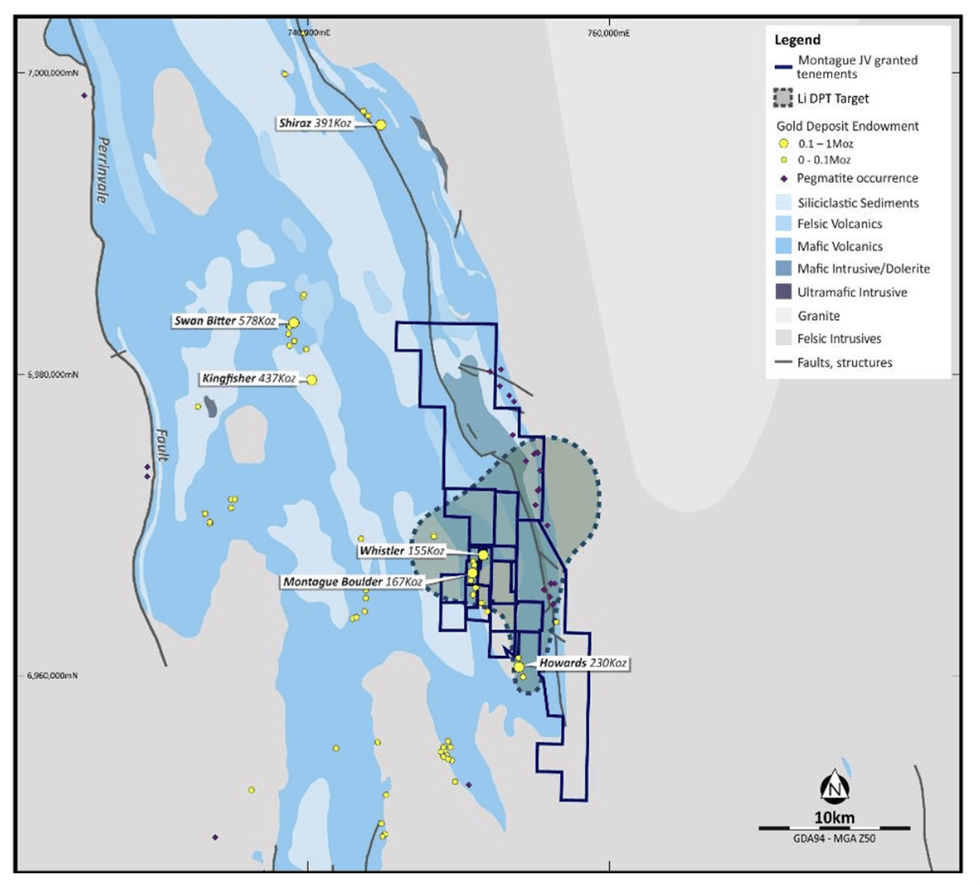

Montague Project

Montague project, located within the Greenstone Belt, is a joint venture between Premier1 and Gateway Mining. Premier1 can earn up to 80 percent interest in the JV by meeting certain expenditure criteria. Premier1 has selected tenements within the Montague project for lithium, using AI and machine learning.

The project comprises historical mining leases and is situated in proximity to geological formations that indicate the presence of lithium-bearing pegmatites.

Land access approvals are in place for the project and the next steps include pegmatite mapping and sampling, and soil geochemistry, which will be followed by drilling in H2 2024.

Gecko North Project

Gecko North project is a joint venture between Premier1 and LithGold Minerals. The company used AI and machine learning to generate lithium targets at Gecko North. Premier1 can earn up to 80 percent interest in this JV project. This includes earning 51 percent interest by spending $2.5 million over four years, and an additional 29 percent interest by completing a bankable feasibility study.

Land access approvals for this project are in place and the next steps include extending soil geochemistry and shallow drilling to test soil anomaly in H1 of 2024.

Management Team

Richard Taylor – Executive Director and CEO

Richard Taylor is a qualified lawyer and holds an MBA from Cambridge University and a master’s degree in law from ANU. He has more than 15 years of experience and has held several senior leadership roles in the resource sector. Previously, he has worked with Terramin Australia, Mineral Deposits, PanAust, MMG, and Oxiana. His experience spans various domains including strategy, business development and governance.

Anja Ehser - Non-Executive Director

Anja Ehser is a geologist with over 15 years of experience in the mineral exploration sector in Europe, and Canada, focusing on base, precious and battery metals. She has held several senior leadership roles within the Deutsche Rohstoff Group and its subsidiaries.

Nicholas Limb – Non-Executive Chairman

Nicholas Limb is a professional geoscientist. He has held senior-level positions in various ASX-listed companies in the gold, mineral sands, and oil and gas sectors. He has rich experience in multiple domains including finance, risk and governance.

This article was written in collaboration with Couloir Capital.

Premier1 Lithium Investor Kit

- Corporate info

- Insights

- Growth strategies

- Upcoming projects

GET YOUR FREE INVESTOR KIT

Investing News Network websites or approved third-party tools use cookies. Please refer to the cookie policy for collected data, privacy and GDPR compliance. By continuing to browse the site, you agree to our use of cookies.